The Power of Data: Optimising Performance

Welcome to the second instalment of our Nissan Formula E Team-inspired blog series, where we explore the world of data. In both motorsports and EV infrastructure, data unlocks performance, efficiency, and operational excellence.

In this edition, we’ll explore how data powers Nissan Formula E Team’s performance and how Electromin’s Charge Point Management System (CPMS) brings similar precision to EV charging solutions.

The Power of Data in Formula E Racing

Data is the lifeblood of Formula E racing, driving every aspect of team strategy and performance optimization. For Nissan Formula E Team, this data journey begins well before race day, with extensive pre-race analysis that leverages historical race data, track characteristics, and car metrics. This preparation allows the team to simulate various scenarios, refine energy consumption strategies, and anticipate potential challenges.

Dorian Boisdron, Team Director of Nissan Formula E Team, underscores the depth of this process, explaining how familiar tracks allow them to “improve our track models to have a better correlation between the simulation/simulator activities and real life.” This meticulous approach ensures that every race is an opportunity to fine-tune the car’s setup and strategy, using specific key performance indicators and data science analysis techniques.

Boisdron highlights the practical application of this strategy during Season 10 in Diriyah, where they identified that the main limiting factor was rear tyre temperature. “We adjusted our strategy to use Attack Modes earlier, which helped manage tyre wear and optimize performance,” he recalls, demonstrating how data-driven insights directly influence race outcomes.

Another instance in Sao Paulo demonstrated the importance of battery temperature management. Boisdron shares, “We knew the battery temperature management would be tricky, so we avoided saving energy early in the race, pushing to the front to manage the battery heat better later”. These strategic adaptations, guided by rigorous data analysis, showcase the profound impact of data on race outcomes.

During the race, while real-time communication with the car is limited by Formula E regulations, data still plays a critical role. Drivers rely on dashboard data, such as battery state of charge and temperature, to make instantaneous decisions. Boisdron explains, ” during the race briefing, we are giving them some references so they can ultimately make key and fast decisions themselves during the race according to what they see on their dashboard.”

Data Driven Improvements Post-race

Post-race, the data collected is analyzed extensively to understand what happened and to inform future strategies. Boisdron notes, “After a race, we ensure a good understanding by analyzing our car data and timing data, rewatching video footage, and listening to every car’s radio.” This thorough analysis helps identify areas for swift adjustments, such as tyre management or strategy tweaks, and supports the development of new software features for mid-term improvements.

The seamless integration of data at every stage of the race ensures that Nissan Formula E Team remains a formidable force on the track, continuously pushing the boundaries of what is possible in electric racing.

Just as Nissan Formula E Team relies on data for race performance, Electromin leverages data to optimize EV charging networks.

Electromin’s CPMS: Data-Driven Charging Solutions

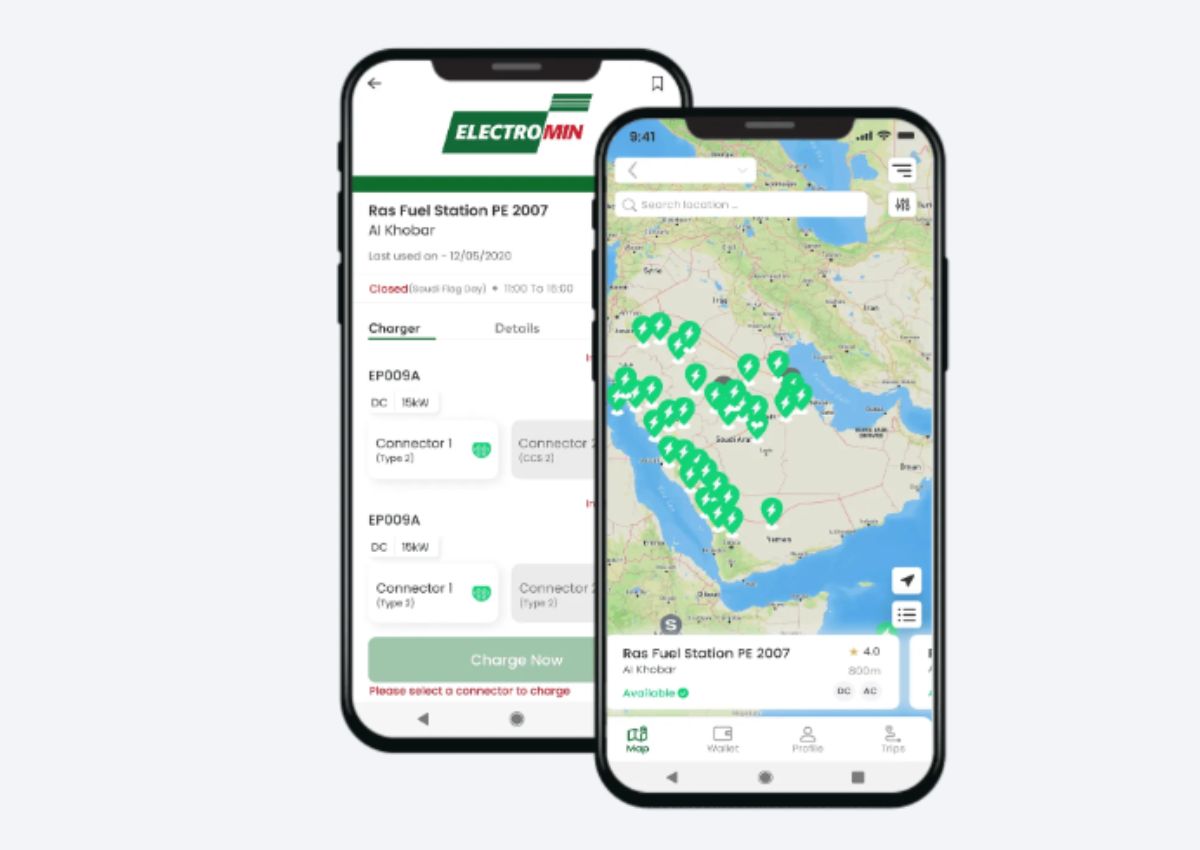

Data is the engine behind Electromin’s Charge Point Management System (CPMS), which powers EV charging networks across Saudi Arabia. Like Nissan Formula E Team monitoring every car detail during a race, Electromin’s CPMS constantly tracks charger performance to ensure everything runs smoothly for both businesses and EV drivers.

Fizza, Electromin’s CPO Manager, explained how real-time data keeps the entire charging network optimized: “Our CPMS constantly monitors chargers, checking if they’re available, in use, or experiencing a fault. This live data is instantly fed into the Electromin app so EV drivers can see charger availability and plan their routes without any surprises.”

But it’s not just about convenience for drivers. The same data-driven approach also helps businesses that manage charging stations. “For businesses, data from the CPMS provides critical insights like charger uptime, energy usage, and which locations are popular charging hubs. This helps them make smarter decisions about when and where to expand or upgrade chargers,” Fizza added.

Perhaps the biggest advantage is that Electromin’s CPMS allows for remote monitoring and troubleshooting. “We can fix many issues through the software itself without sending technicians on-site. It saves time, reduces costs, and keeps chargers running at their best.”

Real-Life Applications: Data in Action

The power of Electromin’s CPMS isn’t just theoretical—it’s already making a difference in the field. Fizza shared how data-driven problem-solving helped resolve two major challenges in recent months.

“We noticed several chargers experiencing connectivity issues due to weak network signals from a specific service provider,” she explained. “Our team tracked the signal patterns and upgraded the system with a multi-provider SIM card. This instantly improved service reliability—all through remote monitoring without a single site visit.”

In another case, Electromin spotted a recurring fault called an ‘E-lock failure’ affecting chargers from a particular OEM. “By analysing charger behaviour through our CPMS logs, we saw a clear pattern emerging. Instead of sending technicians to troubleshoot one charger at a time, we collaborated with the OEM to create a software update that resolved the issue for all affected chargers in one go.”

These examples highlight the power of data-driven EV infrastructure management. With Electromin’s CPMS, it’s not just about fixing problems—it’s about predicting and preventing them to keep the network running seamlessly.

Data Synergy: From Track to Charger

The parallels between Nissan Formula E Team’s use of race data and Electromin’s CPMS highlight a shared commitment to precision and innovation. Both understand that data isn’t just numbers—it’s the key to better decisions and superior outcomes.

Whether winning races or optimizing EV infrastructure, the right data at the right time makes all the difference.

Stay Tuned for More Insights

In our next post, we’ll explore how innovation drives Nissan Formula E Team’s success and Electromin’s mission. From advancements in battery technology to real-world applications, we’ll uncover how these breakthroughs shape the future of electric mobility.

Ready to power your business with data-driven charging solutions? Visit Here to learn how we can help you stay ahead of the curve.